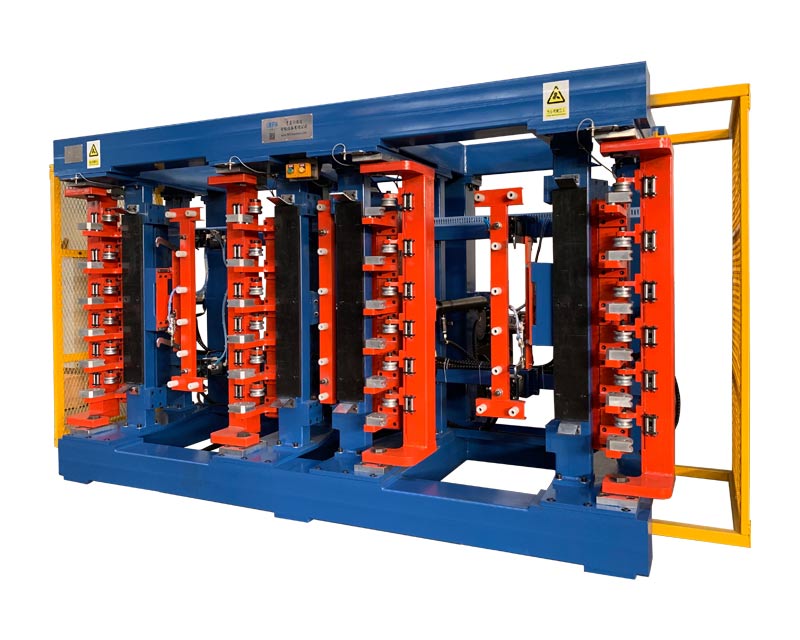

1、 Product Description

The IBC frame bending machine is used for bending ton bucket mesh into rectangular frames with dimensions of (1200 ± 5mm) × (1000 ± 5mm).

2、 Performance characteristics:

This machine consists of (1. Rack) and four sets of bending systems, with the left two sets being the same and the right two sets being the same. The left two sets are symmetrically arranged with the right two sets. Through (2. Three axis hydraulic synchronization mechanism), the bending module moves forward, backward, left, right, and up and down, and is combined with (3. Bending cylinder) to push (4. Rotating bending mechanism) to achieve the bending of the mesh. Firstly, the two sets on the outside of the rack are bent, and the two sets on the inside of the rear rack are bent, forming a rectangular metal frame.

Working principle of three-axis hydraulic synchronous mechanism:

The three-axis hydraulic synchronization mechanism achieves synchronous operation through hydraulic cooperation with machinery. This bending machine uses the meshing of gears and racks to synchronize two oil cylinders. It can enhance stability and fold a frame in 15-20 seconds

3、Technical parameters

Rated power | 11Kw |

hydraulic pressure: | 5-10Mpa |

Air pressure: | ≥0.6Mp |

Coolant flow: | ≥60L/min |